Wood better than aluminum for outrunner motor mount balancing out vibrations

lately played outrunner motors, , am still impressed of power , roaring loudness.

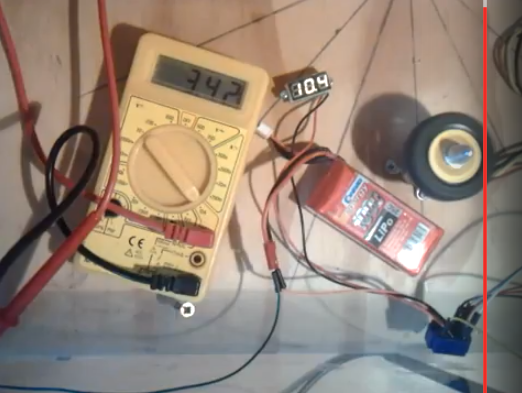

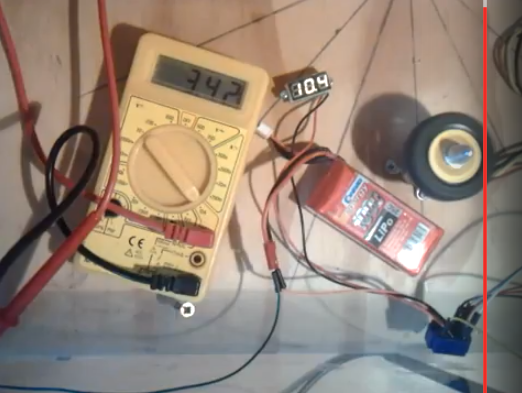

i learned how measure current , measured voltage in parallel on 2nd small voltmeter:

3.42a 10.4v 35.5w, lot ow power single motor.

this screenshot shows run balanced out wheel (im not interested in propellers).

in trying balancing out second wheel (which need 2nd outrunner motor circular running robot in motor test station) did break legs 2 aluminum motor mounts , 1 leg third aluminum mount. see quite movies on hermannsw youtube channel

i bought 5pcs set of aluminum mounts 6 days ago, have wait 21-47 days delivery. , not real balancing out, because more aluminm legs break:

https://www.aliexpress.com/item/4pcs-2204-2212-2208-2216-2218-22-brushless-outrunner-motor-mount-x-type-cross-holder/1951976788.html

today built own motor mount 4mm thick wood (click detailed view):

the distances between 2 opposite screws of a2212 type motor 19mm , 16mm. , in middle whole needed center moving motor part. screws had long, shortened them adding screw nuts. construction firm, , works better aluminum mounts high vibration runs one:

https://www.youtube.com/watch?v=dx7e-nckzfy&feature=youtu.be

i did drill holes different diameter screwdrivers, , cut wood saw kitchen knife shown above.

hermann.

i learned how measure current , measured voltage in parallel on 2nd small voltmeter:

3.42a 10.4v 35.5w, lot ow power single motor.

this screenshot shows run balanced out wheel (im not interested in propellers).

in trying balancing out second wheel (which need 2nd outrunner motor circular running robot in motor test station) did break legs 2 aluminum motor mounts , 1 leg third aluminum mount. see quite movies on hermannsw youtube channel

i bought 5pcs set of aluminum mounts 6 days ago, have wait 21-47 days delivery. , not real balancing out, because more aluminm legs break:

https://www.aliexpress.com/item/4pcs-2204-2212-2208-2216-2218-22-brushless-outrunner-motor-mount-x-type-cross-holder/1951976788.html

today built own motor mount 4mm thick wood (click detailed view):

the distances between 2 opposite screws of a2212 type motor 19mm , 16mm. , in middle whole needed center moving motor part. screws had long, shortened them adding screw nuts. construction firm, , works better aluminum mounts high vibration runs one:

https://www.youtube.com/watch?v=dx7e-nckzfy&feature=youtu.be

i did drill holes different diameter screwdrivers, , cut wood saw kitchen knife shown above.

hermann.

if system imbalanced produce enough radial force damage mount,

you overloading motor ball-bearings massively.

you can't away grossly imbalanced high speed rotor. presume using wheels

at higher rpm designed for. can lead violent mechanical explosion

if wheel isn't strong enough.

which wheels trying spin @ speed?

if wheels can cope speed, you'll need sort of universal joint linkage remove

the imbalance forces , vibration motor shaft , keep happy. bearings for

the wheel need rugged enough forces involved, ie large.

you overloading motor ball-bearings massively.

you can't away grossly imbalanced high speed rotor. presume using wheels

at higher rpm designed for. can lead violent mechanical explosion

if wheel isn't strong enough.

which wheels trying spin @ speed?

if wheels can cope speed, you'll need sort of universal joint linkage remove

the imbalance forces , vibration motor shaft , keep happy. bearings for

the wheel need rugged enough forces involved, ie large.

Arduino Forum > Using Arduino > Motors, Mechanics, and Power (Moderator: fabioc84) > Wood better than aluminum for outrunner motor mount balancing out vibrations

arduino

Comments

Post a Comment